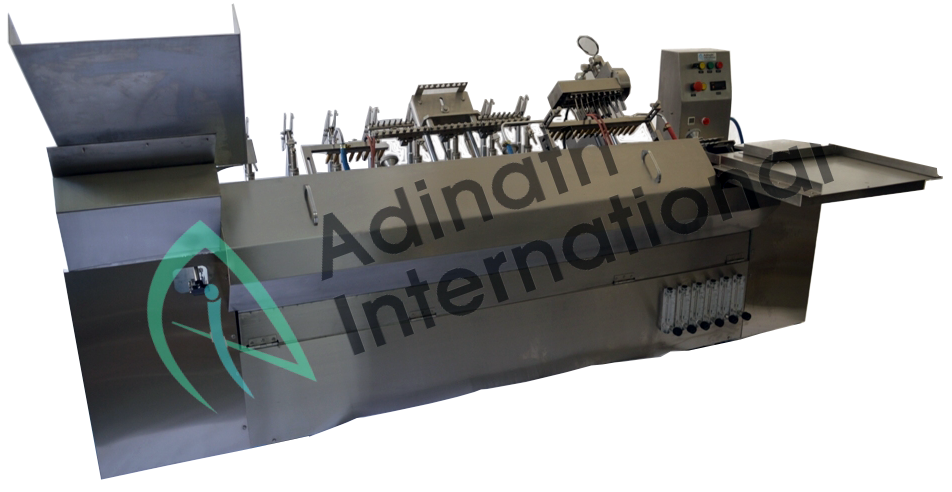

Closed Ampoule Filling Sealing Machine is uses for filling and sealing of type D pre sterilized closed ampoules. Machine built on principle of slant travel of ampoules while filling and sealing, to take care of vide variation of ampoule neck dimensions, thicknesses of available standard ampoules.

The Filling unit built on Stainless Steel Square pipe frame and totally encompassed with Stainless Steel Coverings, in pleasing matt finish. Further, large opening available at bottom side of the machine for easy cleaning. The pendant type electrical control panel is lifted from machine for ease of operation and safety. Machine is suitable for ampoule filling in pharmaceutical, cosmetic, agriculture and chemical industries.

Pre Sterilized D type Ampoule tray can be directly loaded into slant hopper of the machine. The magazine type cassette delivers closed ampoules on moving eccentric ampoule rack in one/two/four/six/eight’s. Ampoule rotating lever rotate the ampoules and extreme pressure of the gas heat the ampoules. Ampoule opening process is done by the manner of pre-heating and opening with the pressure of the gas (LPG + oxygen). During the stoppage of rack sequentially ampoule opening, pre-gassing, filling, post gassing, pre-heating and final sealing is achieved. Filled & sealed ampoules are collected automatically in SS tray in upright position without hand touch.

| Model | AFS – 30C | AFS – 55C | AFS – 100C | |

|---|---|---|---|---|

| Direction of movement | Left to right | Left to right | Left to right | |

| Production Output | 15 to 30 Ampoules/Minute (depends upon ampoule size) | 30 to 50 Ampoules/Minute (depends upon ampoule size) | 50 to 100 Ampoules/Minute (depends upon ampoule size) | |

| No. of Filling Heads | Single | Two | Four | |

| Ampoule Size | 1ml to 10ml | 1ml to 20ml | 1ml to 5ml | |

| Filling Accuracy | -±1% | -±1% | -±1% | |

| Power Supply | 1 H.P. | 1 H.P. | 1 H.P. | |

| Electrical Characteristics | 220 Volts, Single Phase, 50 Hertz | 220 Volts, Single Phase, 50 Hertz | 220 Volts, Single Phase, 50 Hertz | |

| Opening & Sealing Gas | LPG + Oxygen (O₂)) | LPG + Oxygen (O₂) | LPG + Oxygen (O₂) | |

| Nitrogen Pressure Required: | 1kg/Cm² | 1kg/Cm² | 1kg/Cm² | |

| Oxygen Pressure Required: | 1kg/Cm² | 1kg/Cm² | 1kg/Cm² | |

| LPG Pressure Required: | 0.5Kg/Cm² | 0.5Kg/Cm² | 0.5Kg/Cm² | |

| Overall Dimension | 1100mm (L) x 650mm (W) x 965mm (H) | 1200mm (L) x 800mm (W) x 965mm (H) | 1400mm (L) x 1150mm (W) x 965mm (H) | |

| Net weight | 110 Kgs. Approx. | 200 Kgs. Approx. | 350 Kgs. Approx. | |

| * Power voltage can be adjusted as per customer’s domestic power voltage requirements. * Rights of technical improvements & modification reserved. * Illustrations & dimensions are shown for information purpose only. |

||||

| Note: Electrical characteristics can be adjusted as per customer’s domestic power requirements. | ||||

© 2017 - All Rights with Adinath International